How Japanese Matcha Green Tea Powder is Made

Matcha is a finely ground green tea powder made from shade-grown Camellia sinensis tea leaves, specifically tencha (碾茶). Unlike other teas such as black, white, oolong, and even other types of green tea, matcha follows a distinct cultivation and processing method that enhances its umami flavor, vibrant green color, and high caffeine content.

What sets authentic Japanese matcha apart is its 800-year-old history of cultivation, with many farmers still following traditional methods to this day.

In this article, we will take you through the Japanese matcha green tea production process, step by step, from how its made to what matcha is made of.

The Shading Process

The production begins with a meticulous shading process, which takes place 3 to 4 weeks before harvest.

Farmers cover the Camellia sinensis plants with woven straw or synthetic screens, blocking direct sunlight. This process is essential for producing high-quality matcha because:

- Less sunlight increases the plant’s production of amino acids, enhancing its sweet and umami flavors.

- Higher chlorophyll levels give matcha its deep green color.

- Natural sugars and caffeine balance improve, leading to a smooth, rich taste.

While the exact shading period depends on the tea farm and its region in Japan, this step is crucial for developing the characteristic depth and complexity of Japanese matcha green tea powder.

Why is shading important?

Shading enhances the tea leaves’ flavor, caffeine content, and natural sweetness. With less sunlight exposure, the plant increases the production of amino acids, particularly L-theanine, which contributes to matcha’s signature umami taste. This process also slows down the production of catechins, which are responsible for bitterness, ensuring a naturally sweeter flavor.

The Harvesting Process

Once the shading process is complete, it is time to harvest the tea leaves. In Japan, the first harvest, known as hachiju-hachiya (八十八夜), occurs on the 88th day after the first day of spring—a significant marker for tea farmers. This usually falls between mid-April to mid-May, depending on the region and climate conditions.

The first harvest produces the highest-quality matcha, featuring the most vibrant green color and richest flavor. While machine harvesting is common for efficiency, some smaller farms still handpick their tea leaves for ceremonial-grade matcha, ensuring only the best leaves are selected.

The Steaming Process

Once harvested, the fresh tea leaves undergo steaming, a key step that distinguishes Japanese matcha green tea production from other tea-making processes.

- The leaves are quickly steamed (for about 15–20 seconds) to halt oxidation, preserving their bright green color and high amino acid content.

- After steaming, the tea leaves are cooled to maintain freshness.

- The leaves are then dried in ovens, transforming them into aracha (荒茶), or unrefined tea.

At this stage, the leaves have not yet been sorted or ground—they are simply harvested, steamed, and dried.

The Sorting Process

You may wonder, why is sorting tea leaves important? After the steaming and drying process, the aracha begins its journey of sorting for further refinement.

Sorting guarantees that removal of all impurities and dust from the tea leaves. This allows the tea leaves to have similar color, size, and uniformity. Farmers pass tea leaves through multiple sorters and sifters to remove stems and leaf veins. Additionally, they cut the leaves into smaller pieces.

At this stage, farmers refine the aracha into tencha (碾茶). Tencha refers to the tea leaves before they grind them into fine green tea powder.

All high-quality matcha is made from tencha of the first harvest as it has the most vibrant color, richest flavors, and nutrients. Lower-quality, such as culinary-grade matcha, is typically made from older leaves that have been shaded for a shorter period, resulting in a more bitter and duller-colored tea.

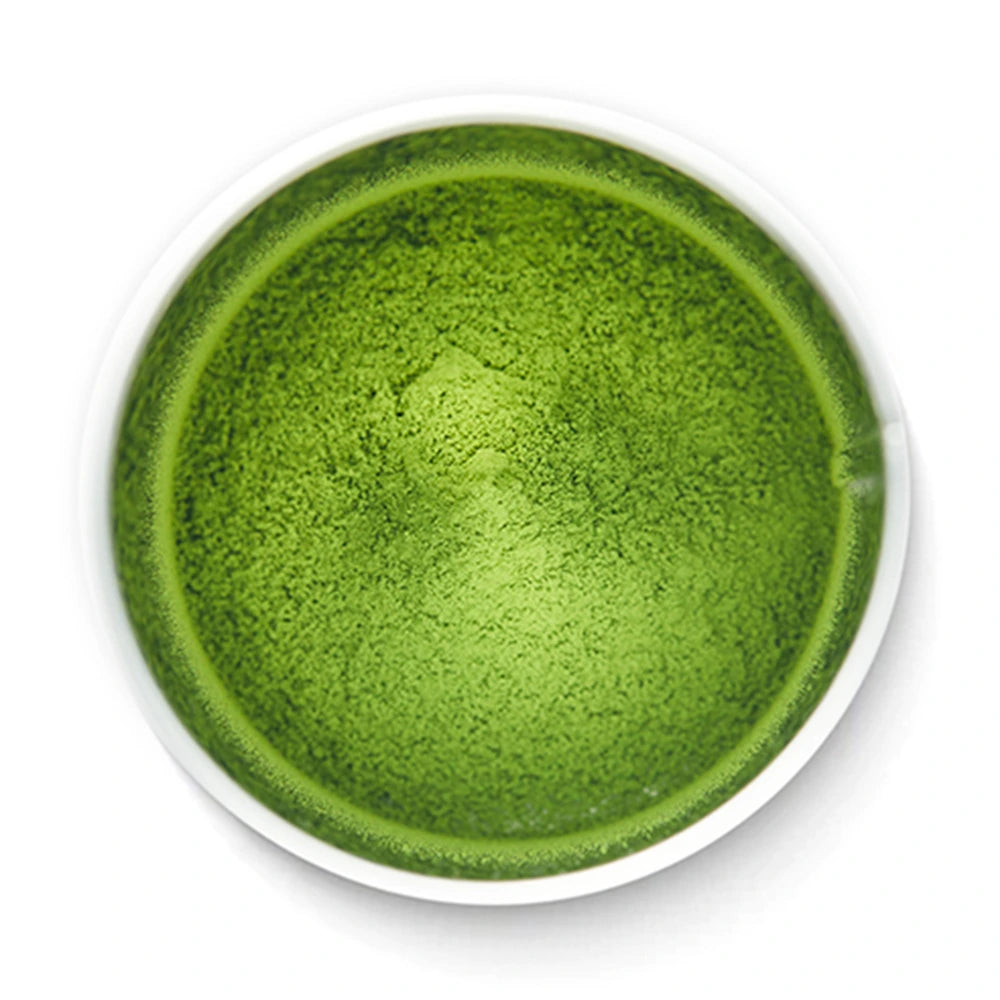

The Grinding Process: How Matcha Is Made Into Powder

The final step in Japanese matcha green tea production is grinding the tencha leaves into a fine powder.

Traditionally, stone mills were used to grind the tea leaves slowly by hand, ensuring a fine, smooth texture. However, this process was labor-intensive and created heat from friction, which could affect the tea’s flavor and nutritional profile.

Today, modern grinding machines allow for a more efficient and controlled process, ensuring matcha retains its delicate balance of flavor and nutrients. Once ground, matcha is immediately packaged to preserve freshness, color, and aroma.

The Art Behind Every Cup of Green Tea

From careful cultivation to the final grind, the journey of transforming tea leaves into a fine, the vibrant matcha powder is a testament to centuries of expertise and tradition. Each step—shading, harvesting, steaming, sorting, and grinding—plays a vital role in shaping the flavor, color, and quality of the final product.

The dedication of Japanese tea farmers and artisans ensures that every sip delivers a smooth, umami-rich experience, steeped in history and craftsmanship. Understanding this intricate process allows us to truly appreciate the skill and care that goes into producing such a refined green tea.

For those who seek the highest quality, exploring teas made with these time-honored methods offers a deeper connection to both the culture and the craft behind them.

🍵 Drinking our tea? Snap a pic and tag us on Instagram at @senbirdtea or #senbirdtea. We’d love to see your moment with tea!

If you want to read more articles on matcha, check them out here:

- 4 Health Benefits of Matcha Green Tea Powder

- New Year, New Rituals – A Modern Guide to A Matcha Tea Ceremony at Home

- How to Prepare Matcha: Usucha vs. Koicha

- The Caffeine Content in Matcha Green Tea versus Coffee

- A Matcha Green Tea Cheesecake Recipe

- 5 Unique Matcha Drink Recipes

- How to Make Matcha Banana Bread

- Strawberry Cream Matcha Shortbread

- Matcha Cupcakes with Matcha Cream Cheese Frosting

- Matcha Shortbread Cookies with Milk Glaze

- Matcha Apple Pie Ovenight Oats Recipe

- Matcha Milk and Honey Bread Recipe

- Creamy Matcha Green Tea Popsicle Recipe

Share your moment with us and stay connected on: